Project development goals are to:

- Conduct detailed ground and aeromagnetic surveys over the northern sections of the EPM to delineate major magnetite mineralisation;

- Carry out drilling of resource in northern portion of ‘Central’ orebody to JORC code compliant measured status for Iron Ore/Magnetite, Ilmenite, Apatite, Zircon and other associated minerals;

- Construct and operate a pilot plant to produce trial quantities of all mineral products;

- Complete a Bankable or Definitive Feasibility study on the unconsolidated Central resource;

- Finalise the EIS to allow a Mining Lease to be granted;

- Complete engineering design of a processing plant that will allow the integration of both hard rock and unconsolidated feed types.

Open pit mining is proposed to a depth of 5-7m using bulldozers. The ore is unconsolidated eluvial, ‘free dig’ and has effectively no overburden. Mineralisation generally occurs up to surface however some lower grade surface areas may be pushed aside to increase ROM grade.

Mining rates will be in the order of 250 tonnes per hour or 2Mt per annum. The scale of mining proposed will not require the use of any unusually sized or configured equipment thus reducing fleet costs and overall mining risk.

Mobile process plant will probably be applied and bulldozer will directly push ore to stockpiles adjacent to the processing plant. This will significantly increase the mining efficiency and also avoid ore double-handling. Tailings dams will be constructed adjacent to the processing plant to store tailings material and reject from the magnetic separation plant. The mineral concentrate will undergo secondary processing through a Mineral Processing Plant (MSP) comprising ilmenite, zircon, rutile, corundum, apatite and feldspar circuits.

Tailings produced from processing the ore will be de-watered and placed back into the pit with slimes. A newly developed and proven process of ‘co-disposal’ will allow slimes and sand tailings to be mixed prior to disposal and a significant proportion of the contained water to be recovered and recycled back into the processing plant. Additional processing water will be extracted under license from the Burnett River Dam.

The mineral product will then be transported to Bundaberg using B-Double trucks via the Gayndah-Mt Perry Road, travelling south via Gooroolba ,Biggenden and Booyal to the Port of Bundaberg. Another possible short-cut through Good Night Scrub National Park is currently under research.

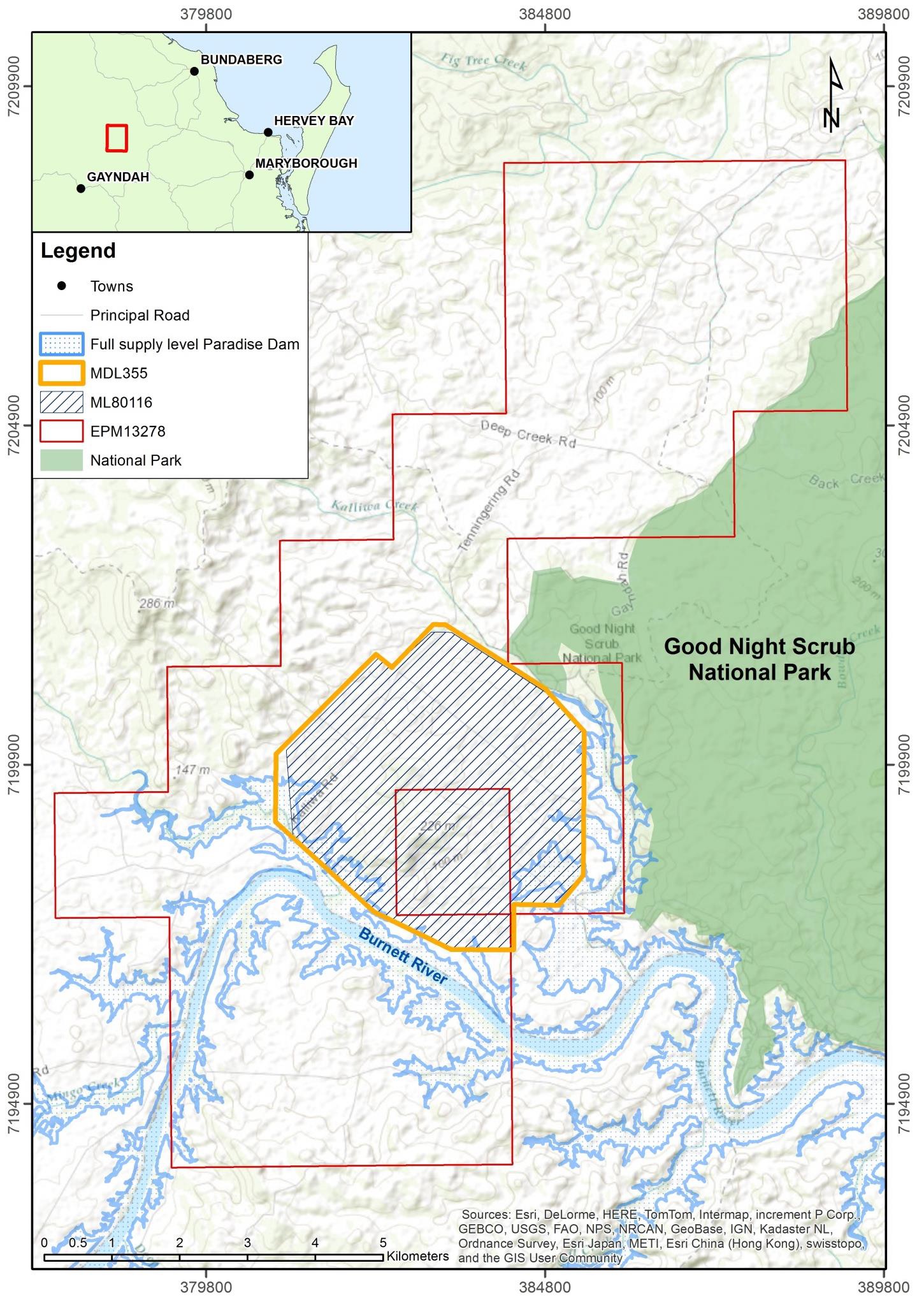

Figure 4. Aerial photograph of the MDL & MLA shown in orange outline representing the central project area.